Iron Man II Arc Reactor Toy: Advanced Modification Part I

[19042010 2300]

Some new ideas

OK, so I had my fun with the toy and then, less than a week later, I realised that with just three LEDs, the modified Arc Reactor is not going to cut it. It has to be brighter. Much much brighter. It does not have to be blindingly bright but 'looks the business' bright. I just want the Arc Reactor toy to show that it has a lot of lights in there. And after talking with Pete, we realised that, more or less why the LEDs were yellow in the first place. Apart from prolonging the battery's life, yellow LEDs do not actually blind you when you stare at it directly, even for one second. Imagine a kid staring at it and then start running around the house, blind as a bat......

While thinking up of other ways to bring the concept to reality, I will now share with you some other things I have discovered.

Idea #1: Just the lights, Sir.

Pete did ask me if I can just bypass the toy circuit and light up the reactor. After tinkering a bit with come connector cables, I found out that is is possible. But the disadvantage would be that you would need to put in a switch as what you now have would effectively be a very inefficient 3 LED torch. But if you have a lot of time to spare, you could also remove the whole circuit and replace it with those ready-made circular/halo "Angel Eyes" LEDs meant for car headlamps. But you would need to modify the resistors as they were designed to take only 12 volts. The total voltage for the two AAA batteries are 3 volts.

So, in order to impress the girls, you just take a short piece of wire from the red cables near the [+] battery terminals (on the right) and connect it to the red cables that led to the PCB where the three white LEDs were (on the left). In between, you can connect a switch to this wire. Make sure you have a fresh pair of AAA's before you show it off to the chicks, especially those who are technically inclined, who know their LEDs and love Energizers. (Ahem) |

A quick one: I took a shortcut by using a ready made H4 circular/halo LED ring as I do not have one that has 5cm in diameter. As you can see, one of the circuit boards has to go. There is really not enough space in the toy. So, this idea is out of the window unless I do not mind cutting that H4 PCB up into three pieces for the two PCBs to co-exist together. The reason is because of the three grey switches which also acts as support pillars to the transparent plate cover. As it is actually touching that plate, the space in between is minimal. Which can be explained in the failure below. |

The problem with the three switches

Let's take another look at the toy again. We know that underneath the cover, there is some space. The main problem is the space or lack of it near the edge of the ring. |

I was still thinking about the H4 LED ring idea and so, I decided to make my own ring, but with a much thinner material. The diameter for the inner ring is about 48 to 50mm with about 8mm width. |

And so, using a hole cutter, I began making my own disk. My intention is to create an 8mm ring inside the toy. |

Bad mistake, after more than half an hour, the blade/scriber was really worn and cracked. |

Finally, a stroke of luck! The stressed plastic cracked leaving the disk intact. But there were a lot of scratches and cutting the inner diameter to create the ring is going to be another blade wasted. So, I tested the piece first. |

Unfortunately (or fortunately for the remaining cutting blades), the disk was too thick because when I put it into the toy, it was pushing against the three switches and the sound/light went on and on. And so, I need something much thinner. Something, as thin as paper...... |

Idea #2: Design Improvement

OK, so those were bad ideas. But I still need a thin ring and the only solution would either be clear acetate or tracing paper. I chose tracing paper because it already has a diffused surface. And also, at this time of night, it was the only material I had. But more to this, I later foudn out that tracing paper withstood my attempts on soldering things on top of it.

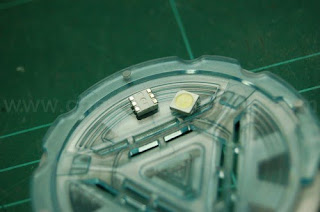

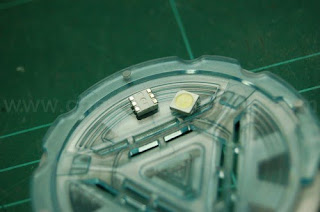

The LEDs I am using are those 5mm x 5mm white SMDs and they have a thickness of about 1mm, which is already a bad idea if I add them to the thick plastic disc I already cut. |

The reason I chose this is because (it was the only SMD LEDs I had) it was large enough to be seen through the toy's 'windows'. Normal SMD LEDs are too small and they would look more like dots. Later on, I will tell you why I chose this. |

This SMD LED actually has three white LED elements inside. Its very difficult to phtograph them as they're very bright. Here, only one element is lit. I am planning to put about nine of them, which means a total of 27 White LEDs, not including the three in the center. But this also means I am using a lot of power from the tiny AAA batteries. |

OK, prototype board says no problem, but its going to be a bit dim. There is no difference in the brightness even if I took away two LEDs per segment. I took away the 1 ohm current limiting resistors as they're making them very dim. Here, the reactor powered the 27 LEDs with no problem. |

Testing the LEDs with the tracing paper (100gsm and not those thin ones for baking). Here, the light diffusion is just right. Although the picture showed the Arc plate to be glowing beautifully, its the DSLR that's making it look nicer. I real life, its so-so. This means I have to remove the 47 Ohm current limiting resistors. |

A closer look at the main reactor plate. The diffusion was good here because there is about 5mm gap between the white LED and the tracing paper. Since I am gluing the SMD LEDs to the tracing paper, I would have 9 dots of lights with the middle glowing. Cool. |

This is a superimposed image of both the cover and the PCB placement. This is how I plan on wiring the LEDs. I would need some thick wires to connect them and also to strengthen the whole assembly. The red lines are positive power rail and the black lines are negative, both will be tapped from the original power to the three white LEDs. The reason why I chose this type of SMD LED is that both sides are flat and so, this means larger surface area which I easily can glue them onto a flat surface of the tracing paper. And not only that, because its SMD (Surface Mount Device) all the legs are conveniently placed on the sides. |