SMD VS THROUGH-HOLE

The advantages of using SMD components (surface mount) as opposed to the conventional though-hole versions is that SMDs are smaller. Because of that SMDs does not consume too much power.

The disadvantage of using SMD components (that exists in millimeters)is that soldering them is really a b*tch.

My original decades old circuits started with a mix of SMDs and through-holes. The former were used to control or generate signals. Over the years, the ratio of SMDs vs though-holes has evolved. Let me just say that, the through-hole components are very good when I need them for prototyping on the stripboard.

THE NEED FOR REFLOW

As technology evolves, so does the SMD components. It is not just enough to miniaturise the components further but also, its footprint on the board. So, there are more and more SMD components with solder pads designed to be placed beneath them. Unfortunately, soldering or repairing these components are not easy and the best method would be solder reflow.

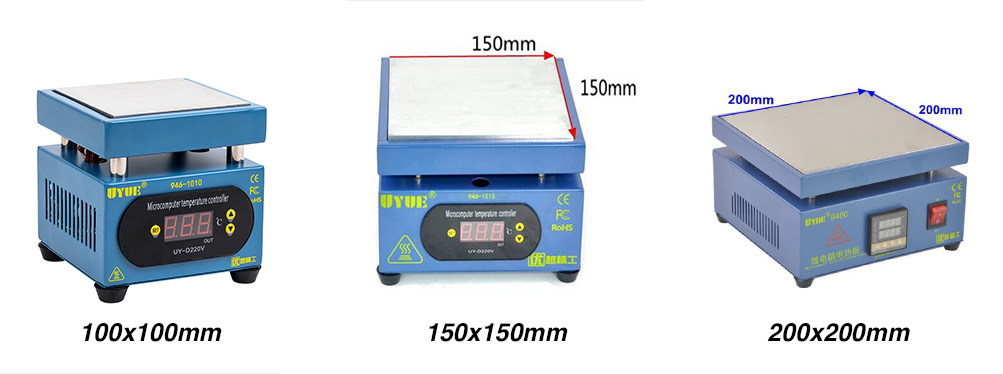

I have thought about it as there is a possibility that I would one day need a reflow equipment. It can either be the ‘traditional’ and bulky reflow oven, a dangerous upside-down clothes iron and some risky hot plate. Most of these are too bulky for my works table since on average, a working space is about 8inches square. But I might want to look at the last option, which is a hot plate. Do near in mind that for reflows, they only work best on one side of the PCB. The components from the opposite side will fall off and/or burnt by the plate while heating your PCB unevenly. This is why I am still not in favour since I tend to populate the PCB on both sides.

WHY I AM NOT IN A HURRY

In any reflow system, you cannot place the PCB on top and watch the solder melt then call it done. The thermal stress induced would be disastrous. In every stage of the reflow process, the temperature is always controlled. The heating of both plate and board, the melting of the solder, the cooling, it is always monitored.

It does look good but that’s still taking up a lot of space.

And it costs over USD100 on average.

SOLDER MASK

And oh, you’d still need to make some solder masks for your PCB. They help deposit the exact amount of solder. At the same time, you can cover a lot more boards in the shortest time possible. A good example is when you have five PCBs, with 30 components, and an average 200 soldering points per board. When you add those up, you’re going to understand why you need reflow soldering.

https://hackaday.io/project/184573-introduction-to-smt-stencils-service

THE HOT PLATE

Looking at this video, the alternative hot plate looks tempting. However, despite having the PCB and other files downloaded, you still need additional tools, namely the Arduino ATMega328p chip. And then you also need an Arduino UNO to program that Arduino chip as well.

To get one ready made, here is the waiting list: https://www.solderreflowplate.co.uk/

For the AfterEarthLTD GitHub files: https://github.com/AfterEarthLTD/Solder-Reflow-Plate